Hoist The Colors: Unveiling Its Dual Meaning And Power

Table of Contents

- The Dual Meaning of "Hoist the Colors"

- The Maritime Legacy: "Hoist the Colours" in Pirate Lore

- Understanding "Hoist": The Mechanics of Lifting

- Practical Applications of Hoisting Equipment

- Choosing the Right Hoist for the Job

- Safety First: Operating Hoists Responsibly

- The Future of Hoisting Technology

- Hoist® Fitness: A Different Kind of "Hoist"

- Conclusion: The Enduring Power of "Hoist the Colors"

The Dual Meaning of "Hoist the Colors"

The phrase "hoist the colors" is remarkably versatile, carrying two distinct yet equally compelling interpretations. On one hand, it evokes the romanticized, often fearsome, world of pirates and their iconic flags. On the other, it refers to the powerful, practical action of lifting heavy objects using specialized machinery. This duality is not merely a linguistic coincidence but a reflection of how the word "hoist" itself has evolved to encompass both symbolic elevation and physical ascension. To "hoist" means to lift or raise, often with the aid of ropes, tackle, or a machine, as highlighted by its dictionary definition. This core meaning is what bridges the gap between a pirate's battle cry and an engineer's essential tool. Understanding both dimensions is key to appreciating the full scope of "hoist the colors."The Maritime Legacy: "Hoist the Colours" in Pirate Lore

For many, the first association with "hoist the colors" is the dramatic image of a pirate ship unfurling its black flag, the Jolly Roger, signaling impending attack or defiance. This powerful symbol, often accompanied by a haunting sea shanty, became synonymous with the golden age of piracy. The act of hoisting the colors was a declaration, a warning, and a rallying cry all in one. It was a moment of truth, signifying that a ship was either preparing for battle or asserting its dominance over the seas. The "colours" in this context refer specifically to the flag, which represented the identity and intent of the vessel and its crew.Origins and Significance in Pirate Culture

Historically, flags were crucial for identification at sea. Naval ships flew national ensigns, while merchant vessels might fly flags indicating their port of origin. Pirates, however, needed a flag that instilled fear and demanded surrender without a fight. The "Jolly Roger" – with its skull and crossbones – served this purpose. The act of "hoist the colours" was not just a procedural raising of a flag; it was a psychological weapon. When a pirate ship was spotted, and the black flag was hoisted, it often meant a choice for the target: surrender and potentially live, or fight and almost certainly die. This ritualistic raising of the flag became deeply ingrained in pirate lore, a chilling symbol of their lawless freedom and formidable power. The song "Hoist the Colours," a haunting sea shanty, perfectly encapsulates this spirit, known by pirates across the seven seas as a call to arms and a testament to their rebellious nature."Hoist the Colours" in Pop Culture: Pirates of the Caribbean

The phrase "Hoist the Colours" gained immense popularity and a new generation of recognition through its prominent feature in the *Pirates of the Caribbean* film series, particularly in *Pirates of the Caribbean: At World's End*. Composed and conducted by the legendary Hans Zimmer, the musical theme "Hoist the Colours" became an iconic piece, capturing the very essence of the pirate world. The song, sometimes written as "Hoist the Colors," is not just background music; it's an integral narrative element. It serves as a powerful call to arms for the members of the Brethren Court, a desperate plea for unity against their common enemies. The lyrics of the sea shanty, "The king and his men / stole the queen from her bed / and bound her in her bones / the seas be ours / and by the powers / where we will, we'll roam," evoke a sense of defiance, a yearning for freedom, and a deep-seated resentment against oppressive authority. This cinematic portrayal cemented "Hoist the Colours" as more than just a historical phrase; it became a cultural touchstone, embodying rebellion, adventure, and the indomitable spirit of those who live by their own rules on the open sea. The emotional weight and epic scale of Zimmer's composition truly bring the act of "hoist the colors" to life for millions worldwide.Understanding "Hoist": The Mechanics of Lifting

Beyond the realm of swashbuckling pirates, the term "hoist" takes on a profoundly practical and critical meaning in various industries. A hoist, in its most fundamental sense, is a machine specifically designed to raise and lower loads that are too heavy for manpower alone. This definition underscores its vital role in construction, manufacturing, logistics, and even home workshops. Hoists typically operate using a drum or wheel around which a chain or rope wraps, providing the mechanical advantage needed to control heavy loads. Whether lifting car engines, heavy machinery, or equipment, hoists are indispensable tools that enhance efficiency, safety, and productivity. The evolution of hoisting technology has transformed how industries operate, moving from purely manual systems to highly sophisticated electric and pneumatic machines. The core principle remains the same: to lift something heavy, sometimes using ropes or a machine, safely and efficiently. This mechanical "hoist the colors" is about lifting components, materials, or finished products into their desired position, often with precision and minimal physical effort.Types of Hoists: Manual, Electric, and Pneumatic

The world of hoisting equipment is diverse, offering solutions tailored to various needs and environments. Understanding the different types is crucial for choosing the hoist that's right for the job. * **Manual Hoists and Pullers:** These are typically operated by hand, requiring physical effort from the user. * **Chain Hoists:** Often found at retailers like Tractor Supply Co. or on Amazon.com, these are popular for their simplicity and durability. They use a chain to lift and lower loads, ideal for tasks like lifting car engines or other heavy machinery where precise, controlled movements are needed without the need for power sources. They are robust and reliable, making them a staple in many workshops and construction sites. * **Lever Hoists (Come-Alongs):** These use a lever and ratchet mechanism to lift or pull loads, often used for positioning or tensioning. Manual hoists are cost-effective, portable, and do not require external power, making them suitable for remote locations or situations where power access is limited. * **Electric Hoists:** These are motorized lifting machines that maneuver loads quickly with minimal physical effort. * **Wired/Wireless Control:** Many electric hoists come with pendant controls or remote wireless controls, allowing operators to maintain a safe distance from the load. * **Speed and Efficiency:** Electric hoists significantly increase productivity, especially in repetitive lifting tasks or when handling very heavy loads. They are commonly used in warehouses, manufacturing plants, and large construction projects. * **Pneumatic Hoists:** Powered by compressed air, these hoists offer several advantages, particularly in hazardous environments. * **Explosion-Proof:** Unlike electric hoists, pneumatic hoists do not produce sparks, making them ideal for use in areas with flammable materials or explosive atmospheres. * **Smooth Operation:** They offer very smooth and precise lifting and lowering, which is beneficial for delicate or high-value items. Pneumatic hoists are often found in chemical plants, paint shops, and certain manufacturing facilities. Each type of hoist has its unique strengths, and selecting the appropriate one depends on factors such as load capacity, lift height, operating environment, frequency of use, and available power sources.Key Components of a Hoisting System

Regardless of their power source or specific design, most hoisting systems share common core components that enable their lifting capabilities: * **Hoisting Mechanism:** This is the heart of the hoist, containing the motor (for electric/pneumatic), gears, and the drum or sheave around which the lifting medium (chain or wire rope) wraps. This mechanism provides the mechanical advantage to "hoist" the load. * **Lifting Medium:** This is either a robust chain or a strong wire rope. * **Chains:** Commonly used in manual and some electric hoists, they are durable and resistant to abrasion. * **Wire Ropes:** Often found in higher capacity electric hoists, they offer smooth operation and high strength-to-weight ratios. * **Hook:** The attachment point for the load, designed to securely hold the item being lifted. Hooks typically feature safety latches to prevent accidental disengagement. * **Trolley (Optional but Common):** Hoists and trolleys transport and position heavy and large loads. A trolley allows the hoist to move horizontally along a beam or rail, providing greater flexibility in positioning the load within a workspace. * **Control System:** For powered hoists, this includes push-button pendants, remote controls, or integrated control panels that allow operators to precisely manage the lifting and lowering actions. * **Braking System:** Essential for safety, the braking system holds the load securely in place when the hoist is not actively lifting or lowering, preventing accidental drops. Understanding these components is fundamental to both operating and maintaining hoisting equipment safely and effectively.Practical Applications of Hoisting Equipment

The utility of hoisting equipment extends across a vast array of industries and applications, making the literal "hoist the colors" a daily reality in countless workplaces. From the smallest garage to the largest industrial complex, hoists are indispensable for managing heavy loads. In **automotive repair and manufacturing**, hoists are critical for lifting car engines, transmissions, and entire vehicle bodies, enabling mechanics and assembly line workers to perform their tasks safely and efficiently. The ability to precisely position heavy components is paramount in these environments. **Construction sites** rely heavily on various types of hoists, including overhead cranes with large hoists, to lift steel beams, concrete slabs, and other building materials to great heights. Without them, the construction of modern skyscrapers and infrastructure would be impossible. In **warehousing and logistics**, hoists integrated into overhead crane systems or standalone units are used to move heavy pallets, containers, and machinery within storage facilities, optimizing space and streamlining material flow. This is where the ability to maneuver loads quickly with minimal physical effort, often provided by electric hoists, becomes a significant advantage. **Manufacturing plants** utilize hoists for a multitude of tasks, from moving raw materials to positioning components during assembly and loading finished products. Specialized hoists are designed for specific tasks, such as handling hot metals in foundries or delicate electronics in cleanrooms. Even in **home workshops and small businesses**, chain hoists and manual pullers are invaluable for attacking a variety of lifting chores with minimal effort. Whether it's lifting a lawnmower for maintenance or moving heavy woodworking equipment, the right hoist can prevent injury and make challenging tasks manageable. Northern Tool, Amazon.com, and Tractor Supply Co. are examples of retailers where one can shop for lift equipment and find a wide selection of hoists, often with free shipping and free returns on prime eligible items, making these essential tools accessible to a broader audience.Choosing the Right Hoist for the Job

Selecting the appropriate hoist is a critical decision that impacts safety, efficiency, and cost. It's not simply about finding a device that can lift the weight; it's about matching the hoist's capabilities to the specific demands of the task and environment. When you need to "hoist the colors" of productivity, careful consideration is key. Here are the primary factors to consider: * **Load Capacity:** This is the most fundamental factor. Every hoist has a maximum weight it can safely lift. Always choose a hoist with a capacity that exceeds the heaviest load you anticipate lifting, providing a safety margin. Overloading a hoist is extremely dangerous and can lead to catastrophic failure. * **Lift Height:** Determine the maximum vertical distance the load needs to be lifted. Hoists are rated for specific lift heights, and exceeding this can compromise performance or safety. * **Power Source:** * **Manual:** Ideal for infrequent use, remote locations, or where precision control at slow speeds is needed. Cost-effective and portable. * **Electric:** Best for frequent, heavy lifting, requiring speed and minimal operator effort. Requires access to electrical power. * **Pneumatic:** Suitable for hazardous environments (e.g., explosive atmospheres) or where extremely smooth and precise lifting is paramount. Requires an air compressor. * **Duty Cycle/Frequency of Use:** How often will the hoist be used? Light-duty hoists are fine for occasional use, while heavy-duty hoists are designed for continuous operation in demanding industrial settings. * **Environment:** Consider factors like temperature extremes, dust, moisture, corrosive materials, or the presence of flammable gases. Some hoists are specifically designed for harsh or hazardous environments. * **Mobility:** Do you need to move the load horizontally? If so, a hoist with a trolley system (manual, geared, or motorized) that runs along an I-beam or monorail is essential. * **Control Type:** Pendant control (wired), wireless remote control, or fixed control panels offer different levels of operator convenience and safety. * **Budget:** While cost is a factor, prioritize safety and suitability over the lowest price. Investing in a quality hoist that meets your needs will pay dividends in safety and longevity. Consulting with equipment suppliers or industry experts can help ensure you make an informed decision, leading to a safe and efficient lifting operation.Safety First: Operating Hoists Responsibly

The power to "hoist the colors" of heavy loads comes with significant responsibility. Operating hoists, whether manual or powered, inherently involves risks if proper safety protocols are not rigorously followed. Adhering to safety guidelines is not just a recommendation; it's a critical requirement to prevent accidents, injuries, and property damage. YMYL principles strongly apply here, as incorrect hoist operation can directly impact "Your Money" (through equipment damage, downtime, and legal liabilities) and "Your Life" (through severe injuries or fatalities). Key safety practices include: * **Operator Training:** Only trained and authorized personnel should operate hoisting equipment. Training should cover safe operating procedures, load limits, inspection routines, and emergency protocols. * **Pre-Operation Inspection:** Before each use, conduct a thorough visual inspection of the hoist, chain/wire rope, hook, and any rigging. Look for signs of wear, damage, or deformation. Never use damaged equipment. * **Understand Load Limits:** Never exceed the hoist's rated load capacity. This is non-negotiable. Always know the weight of the load you are lifting. * **Proper Rigging:** Ensure the load is correctly attached and balanced. Use appropriate slings, shackles, and other rigging hardware that are rated for the load's weight and are in good condition. Avoid sharp edges on loads that could damage slings. * **Clear Work Area:** Ensure the area below and around the load is clear of personnel and obstructions. Use warning signs or barriers as necessary. * **Smooth Operation:** Avoid sudden starts, stops, or jerky movements. Lift and lower loads smoothly and under control. * **Maintain Clear Communication:** If working with a team, establish clear communication signals. * **Never Ride the Load:** Hoists are designed for material handling, not personnel lifting, unless specifically designed and certified for that purpose. * **Regular Maintenance:** Implement a schedule for routine maintenance and professional inspections by qualified technicians. This includes lubrication, checking for wear on moving parts, and testing safety features. * **Emergency Procedures:** Know how to react in an emergency, such as a power failure or equipment malfunction. Understand how to safely lower a load manually if necessary (for hoists with this capability). By prioritizing safety and fostering a culture of responsibility, the powerful act of hoisting can be performed efficiently and without incident, protecting both personnel and valuable assets.The Future of Hoisting Technology

The world of hoisting equipment is continually evolving, driven by advancements in automation, materials science, and digital connectivity. The future of "hoist the colors" in the industrial sense promises even greater efficiency, precision, and safety. * **Automation and Robotics:** Integration with robotic systems and fully automated material handling solutions is a significant trend. Automated hoists can operate with minimal human intervention, following pre-programmed paths to move materials, which is particularly beneficial in repetitive tasks or hazardous environments. * **Smart Hoists and IoT:** The Internet of Things (IoT) is making hoists "smarter." Sensors can monitor hoist performance, detect anomalies, predict maintenance needs, and provide real-time data on load weight, usage patterns, and operational status. This data can be used for predictive maintenance, optimizing workflows, and enhancing safety. * **Enhanced Safety Features:** Future hoists will likely incorporate more advanced safety features, such as collision avoidance systems, intelligent load monitoring that prevents overloading even before it happens, and remote diagnostics capabilities. * **Energy Efficiency:** As industries strive for sustainability, new hoist designs will focus on improved energy efficiency, utilizing more efficient motors and regenerative braking systems. * **Advanced Materials:** Lighter, stronger, and more durable materials will lead to hoists with higher capacities relative to their size, and improved resistance to wear and environmental factors. * **Ergonomics:** For manual and semi-automated hoists, ergonomic design will continue to improve, reducing operator fatigue and strain. These advancements will not only make lifting operations safer and more efficient but also open up new possibilities for how industries manage and move heavy materials, ensuring that the act of "hoist the colors" remains at the forefront of industrial innovation.Hoist® Fitness: A Different Kind of "Hoist"

While our discussion has largely revolved around maritime flags and industrial lifting, the word "hoist" also features prominently in another context: the fitness industry. Hoist® Fitness is a San Diego, California, USA-based company renowned for producing premium strength training products and exercise bikes for both commercial and home markets. This is a fascinating example of how a single word can be adopted to convey a different, yet related, meaning. In the context of Hoist® Fitness, "hoist" doesn't refer to lifting heavy machinery, but rather to the act of lifting weights, building strength, and elevating one's physical capabilities. Their equipment is designed to help individuals "hoist" their fitness levels, challenging muscles and improving overall physical well-being. This brand name cleverly plays on the idea of lifting, raising, and achieving new heights, aligning perfectly with the goals of strength training. It demonstrates the versatility of the word "hoist" and its ability to represent upward movement and improvement, whether it's a pirate flag, a car engine, or a personal fitness goal.Conclusion: The Enduring Power of "Hoist the Colors"

The phrase "hoist the colors" is a powerful reminder of how language can carry multiple layers of meaning, each rich with its own history and significance. From the thrilling legends of pirates raising their defiant flags to the indispensable role of modern hoisting equipment in our industrial world, the core concept of "lifting" or "raising" remains central. Whether it's a symbolic act of rebellion or a precise engineering feat, the act of "hoist the colors" embodies strength, purpose, and the ability to overcome gravity's pull. We've journeyed from the high seas where Hans Zimmer's "Hoist the Colours" echoed as a call to arms, to the factory floors where robust machines lift car engines and heavy machinery with ease. We've explored the different types of hoists, their critical components, and the paramount importance of safety in their operation. Even a company like Hoist® Fitness demonstrates the word's broader application in elevating personal strength. The dual nature of "hoist the colors" makes it a fascinating expression, connecting historical drama with modern utility. It underscores human ingenuity, whether in crafting a fearsome symbol or designing powerful tools. So, the next time you hear or use this phrase, remember its rich tapestry of meanings – a testament to its enduring power and versatility. What does "hoist the colors" mean to you? Share your thoughts in the comments below! If you found this exploration insightful, consider sharing it with friends or delving into our other articles on the fascinating intersection of language and technology.

Hoist the Colors

Hoist the Colors

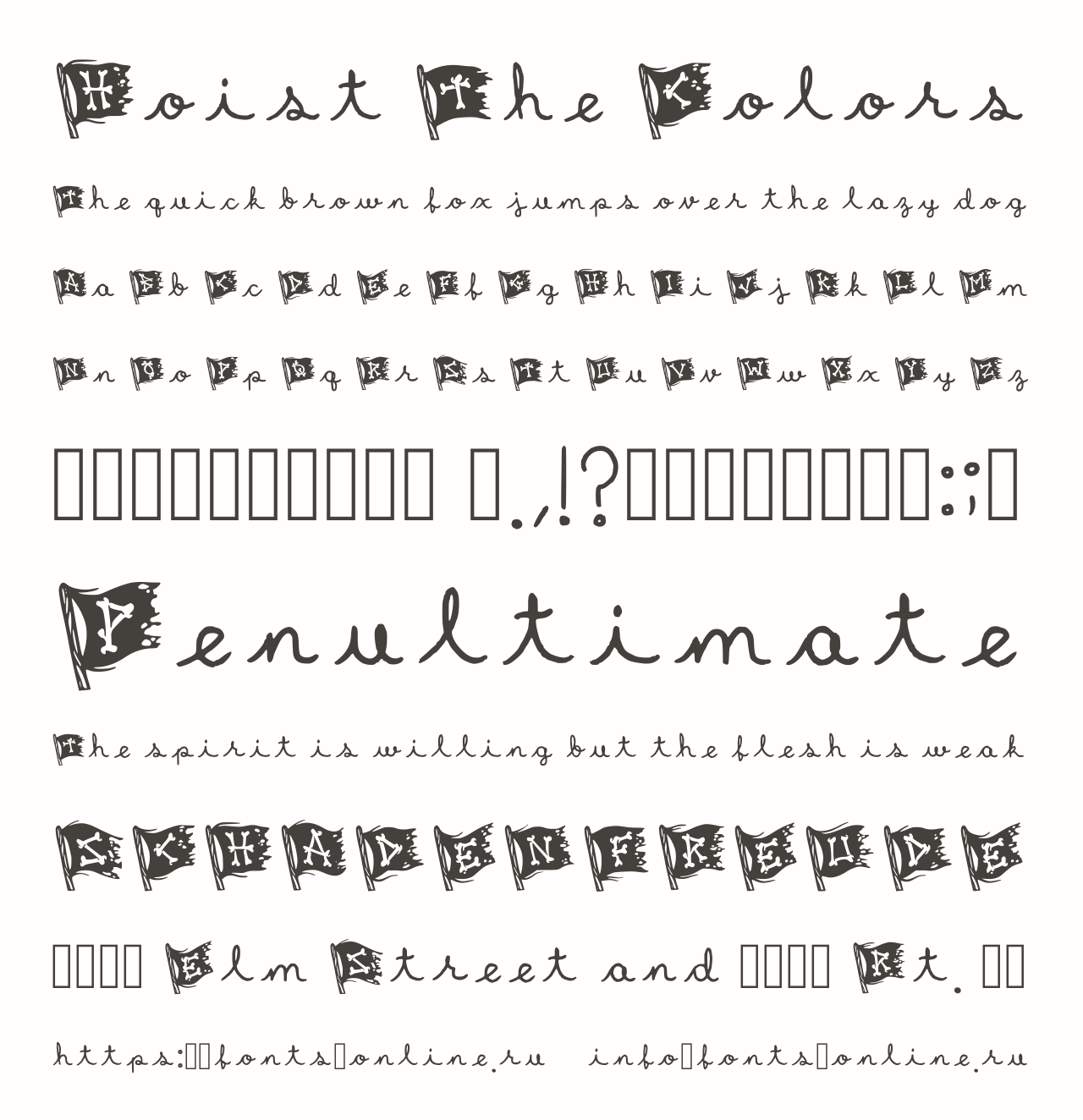

Hoist The Colors font